Our STS XPJ-1682D review covers real-world specs, pros & cons, inks, workflow, costs, and setup tips—so you can decide if this fast 64″ DTF fits your production.

STS XPJ-1682D Review (64″ Direct-to-Film Printer)

📋 Key Specifications — STS XPJ-1682D

| Manufacturer | STS Inks (Japan-built engine) |

| Printheads | Dual staggered (drop-on-demand piezo) |

| Max Resolution / Modes | Up to 1440×1440 dpi; modes 1440/1080/720/360 dpi |

| Media Width / Printable | 64″ media / ~63.6″ printable |

| Media Capacity | 2″ & 3″ cores; ≤ 5.9″ roll Ø; ≤ 66 lb roll weight |

| Head Height Options | Auto adjust; low ~1.5 mm / mid ~2.5 mm / high ~4.0 mm |

| Reliability & Handling | Automatic bi-dir alignment, upgraded feed flange, touch panel, LED lighting (bundle dependent) |

| RIP Software | Flexi DTF Edition (typical), others vary by bundle |

Specs and handling from STS product pages and reseller listings. :contentReference[oaicite:1]{index=1}

The XPJ-1682D pairs wide 64″ coverage with dual-head speed, letting you gang large runs and reduce roll changes. High-res modes keep micro-type clean; automatic height and bi-dir routines help minimize banding at faster passes.

🔍 Performance Analysis — STS XPJ-1682D review

For shops that live on gang sheets, the 63.6″ printable width increases true yield over 30–35″ devices. Dual heads support faster pass counts while retaining smooth gradients in 720–1440 dpi modes. STS positions the platform for “ultra-fast” production and even at reduced resolution the output remains clean—useful for bulk logos and backs. :contentReference[oaicite:2]{index=2}

🔗 Connectivity, RIP & Workflow — STS XPJ-1682D review

Bundles commonly include Flexi DTF Edition for white/CMYK ordering, spot management, and hot-folder queues. Resellers highlight auto bi-directional alignment, a touch panel, LED lighting, and upgraded feed flanges for quicker roll swaps—nice quality-of-life gains for one-operator lines. Build named film presets and lock heater/powder targets per SKU to keep hand-feel and wash fastness consistent. :contentReference[oaicite:3]{index=3}

💰 Running Costs & Uptime — STS XPJ-1682D review

White coverage is the cost lever. At 64″, the waste from mid-job dropouts is expensive—so set RH 40–60%, run quick nozzle checks, and log ink/film by SKU in the RIP for costing. The automatic height and handling upgrades help stabilize laydown on heavier film stocks, which in turn improves powder adhesion and reduces reprints. :contentReference[oaicite:4]{index=4}

🎯 Who Should Buy It? — STS XPJ-1682D review

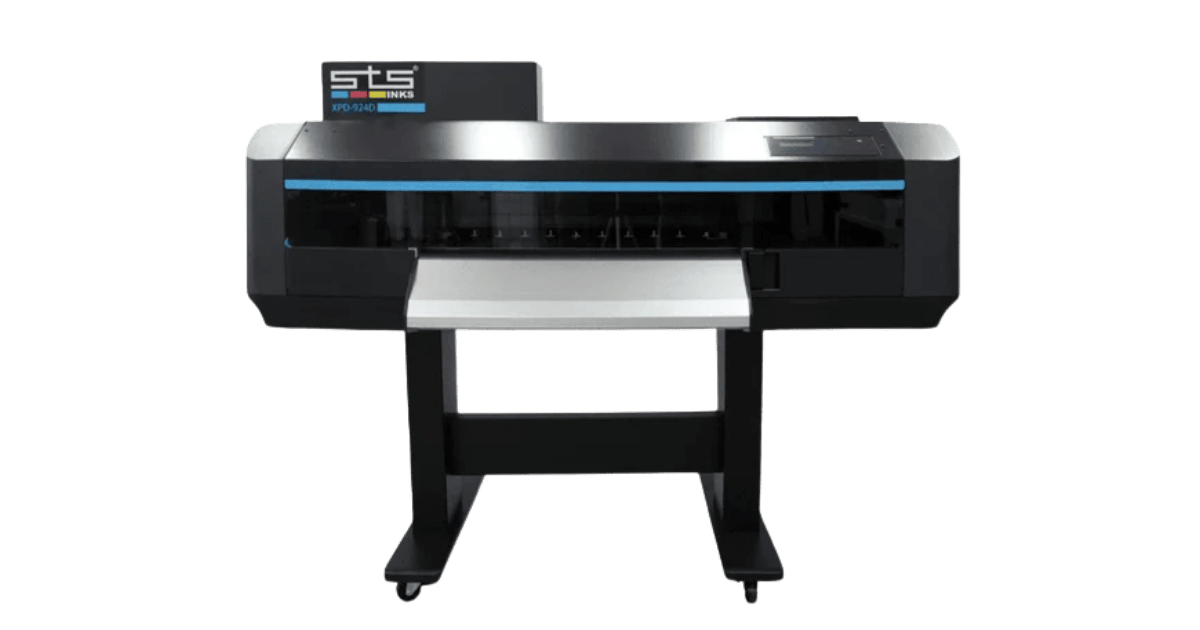

Choose the XPJ-1682D if you need wide-format throughput without stepping to 70″+. If your jobs are smaller or intermittent, a 24–35″ device (or the STS XPD-924D) may be more economical; if you’re permanently volume-constrained, plan on a dual-head 60–63″ line with matched shaker/curer for true lights-out runs. :contentReference[oaicite:5]{index=5}

Explore more: see DTF Printers by Size and our STS XPD-924D review.

❓ FAQs — STS XPJ-1682D review

How wide can it print?

Media width is 64″ with approximately 63.6″ maximum printable width. :contentReference[oaicite:6]{index=6}

Which resolutions are supported?

DTF modes at 360/720/1080/1440 dpi; max resolution up to 1440×1440 dpi. :contentReference[oaicite:7]{index=7}

What media handling does it support?

2″/3″ cores, roll diameter up to ~5.9″, roll weight up to ~66 lb; automatic head-height adjustment. :contentReference[oaicite:8]{index=8}